Tel: 18241241460 (Manager Han)

Phone: 18842014555 (late manager)

Website: www.hcysmzp.com

Address: Lishu Village, Mafeng Town, Haicheng City, Anshan City, Liaoning Province

Website : en.hcysmzp.com

In the early stage of hydration induction, the first exothermic peak was formed within 10 minutes of mixing material shaping.

Hydration induction period is the slow period of hydration reaction within 60 minutes of feeding.

Hydration acceleration period is the second exothermic peak within 240 minutes of feeding.

。

The stabilization period of hydration deceleration is gradually decelerated from the second exothermic peak until stabilization, and the hydration reaction terminates at 14h. Through four stages, light-fired magnesia can be seen that the initial setting time is 1.5 h, the final setting time is 4-5 h, the exothermic curing time is 14 h, the qualified curing time is 20 days, and the cast-in-situ magnesia-oxygen concrete can be dismantled for 6 h.

Calcination temperature and time are the key factors to determine the activity and dispersion of MgO.

The decomposition reaction of magnesite, dolomite and other raw materials in calcination is endothermic reaction. Due to the decomposition of CO 2 and H 2, the product with dense porous crystal structure formed by MgO has good activity and high dispersion (180m2/g). This means that when the product is ground at 400 ~600 C, it will be hydrated in a few minutes at room temperature. Therefore, a good calcination process should control the temperature between 400 ~600 C, which can save energy and improve the quality of products. When the temperature is higher than 900 C, the densification dispersion of the crystal is less than 1300 C, only 3 m2/g, and it takes 75 days to hydrate 95% magnesium oxide at room temperature. Grassen lattice constant shows that the product has the best activity when MgO reaches 0.425 nm and Mg (OH) reaches 0.424 nm at 400 C. That is to say, the optimum temperature is the light burning temperature of 400 ~600 C, which is the source of the light burning powder theory. The longer the calcination time is, the denser the crystal structure will be and it will be difficult to hydrate.

Several elements of optimum mix ratio:

(1) The specific gravity (relative density) of the water solution of the admixture is 1.35-1.50 when the lightweight magnesia-oxygen concrete is prepared. The proportion of water solution in the preparation of lightweight wallboard concrete is 1.50-1.60. The proportion of water solution in light floor, heat insulation board and ceiling concrete is 1.80. The proportion of water solution is 1.9-2.0 in the preparation of fire-proof and waterproof magnesia-oxygen decorative coatings.

(2) The weight ratio of light filler to magnesia (%) in cast-in-situ lightweight concrete - 35. Wallboard - 25. Components - 50. Paint - 10.

(3) The proportion of water solution to the weight of magnesium oxide is 1.60-2.0.

(4) The ratio of magnesium oxide, magnesium chloride and water is 5-5.6:1-1.2:8-11. The proportion of light filler and magnesium chloride is 1-1.3:3-3.9.

Home About Us News Products Environmental Show Contact Us Online Message

National unified contact hotline

18241241460

Address: Lishu Village, Mafeng Town, Haicheng City, Anshan City, Liaoning Province

Copyright ©

http://en.hcysmzp.com/

Haicheng Yongsheng Magnesium Products Manufacturin

Specializing in

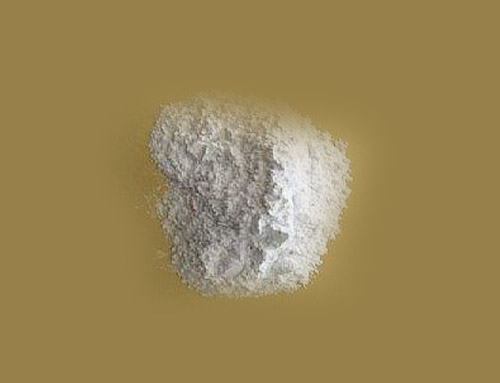

Light burning powder,Light burnt magnesia powder,light burning magnesium oxide

,Welcome to inquire!

Liao ICP No. 17022089-2

Powered by Clouds platform

Technical Support:

Yingkou Zhongchuang Network Technology Co., Ltd.

| Wechat sweep Pay attention to our timely information |