Tel: 18241241460 (Manager Han)

Phone: 18842014555 (late manager)

Website: www.hcysmzp.com

Address: Lishu Village, Mafeng Town, Haicheng City, Anshan City, Liaoning Province

Website : en.hcysmzp.com

Light burnt magnesia powder is an important refractory

Light-fired magnesia powder is a kind of raw material with medium basicity and chemical activity. In addition to being used as refractory and cementitious material, light-fired magnesia powder is also used in other industrial fields. In addition, the development of slag splashing technology for converter protection further expands the application scope of light burning magnesia powder. At present, the slag splashing technology mostly uses light-burned magnesia powder as pellets, such as light-burned magnesia powder pellets, carbon-containing light-burned magnesia pellets and carbon-containing calcium-containing light-burned magnesia powder pellets.

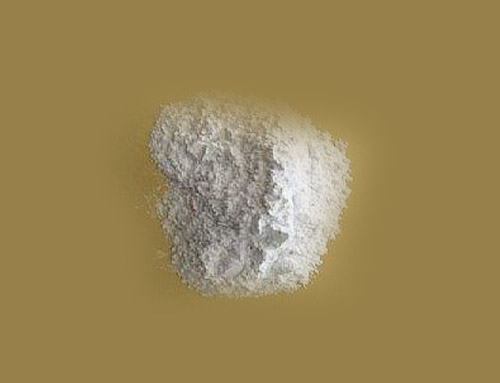

Light-burned magnesia powder, referred to as light-burned magnesia powder, is a kind of active magnesia obtained by calcining magnesite, brucite and magnesium hydroxide extracted from seawater or brine at about 800-1000 C. Light-burned magnesia powder is a light yellow and light brown powder. Its particle size is mostly below 100 mesh. Its crystal density is 3.07-3.22g/cm3. It has large lattice constant, many lattice defects, brittle texture, porous structure and high reactivity. It is easy to react with water to form Mg(OH)2 and harden. It has bonding energy. Power.

Selection of calcination method and control of light-burning temperature are important means to obtain good activity. With the increase of calcination temperature, the specific surface area of MgO decreases significantly. The recrystallization rate of MgO increases, the dispersion decreases sharply and the activity decreases when the temperature is higher than 1000 C. Different calcination methods and equipment at the same temperature are also important factors affecting MgO activity. If calcined in fluidized bed furnace and suspension furnace, it can decompose rapidly in an instant, and the lightly burned magnesia powder with the greatest activity can be obtained. Using tunnel kiln and reflective kiln as large blocks, the calcination time is long, and the surface is often overburned while the interior is burned, which will reduce the activity of light-burned magnesia powder. The calcination of granular magnesite in rotary kiln is between the two conditions, and the light-burned magnesia powder can also be obtained to maintain better activity.

The weight of each batch of finished product is not more than 120 t.

Samples for particle size determination should be sampled before group batches, and samples for chemical analysis should be sampled after group batches. Samples were taken in small bags (25kg) for every 20 bags and in large bags (1000kg).

After fully mixing the obtained particle size samples, the particle size was determined by point sampling of 10-20g. The mixed samples were reduced to 200 g and sent to the laboratory for analysis.

If a chemical composition is unqualified or abnormal, double quantity of samples will be re-examined in the same batch of products, and the re-examination results will be the final inspection results of the batch of products.

Home About Us News Products Environmental Show Contact Us Online Message

National unified contact hotline

18241241460

Address: Lishu Village, Mafeng Town, Haicheng City, Anshan City, Liaoning Province

Copyright ©

http://en.hcysmzp.com/

Haicheng Yongsheng Magnesium Products Manufacturin

Specializing in

Light burning powder,Light burnt magnesia powder,light burning magnesium oxide

,Welcome to inquire!

Liao ICP No. 17022089-2

Powered by Clouds platform

Technical Support:

Yingkou Zhongchuang Network Technology Co., Ltd.

| Wechat sweep Pay attention to our timely information |